Many would say that a person’s smile is their most attractive physical attribute. But not everyone has a naturally flawless set of whites. Millions of people worldwide need assistance from dental professionals, meaning there’s a long wait for aligners and dental models.

Thankfully, waiting time for patients can go down, and dental models can be created around the world without breaking the bank. The reason? A fast-growing startup that makes both the machine and materials for dental 3D printing.

The early-stage VC internship search

Structo is a deeptech 3D printing solutions provider headquartered in Singapore.

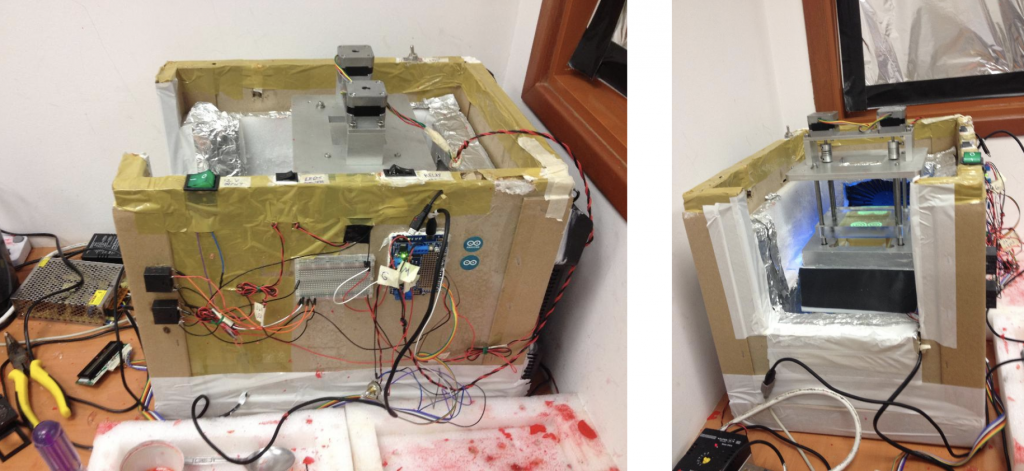

Back in 2014, the people behind the company had a different path in mind for their proprietary Mask Stereolithography (MSLA) printing technology, and it certainly didn’t involve dental braces.

As company founder Huub van Esbroeck explains, “We wanted to steer clear of dental and medical applications because we had the impression it would be a very challenging path in terms of regulatory approvals with FDA, CE, HSA, etc.”

Huub’s fellow co-founders were fellow mechanical engineering undergraduates from the National University of Singapore.

Instead, he and his co-founders (and fellow mechanical engineering schoolmates from the National University of Singapore or NUS) were interested in 3D printing’s engineering and manufacturing applications, particularly in the automobile and aerospace industries.

With no moving parts, and using a digital mask to control which parts of the resin should be simultaneously lit up to create a printed layer, Structo’s MSLA tech initially sounded like a good fit for faster and more cost-effective production in these industries.

But they also quickly recognized a downside. Huub frames it as a mismatch between their tech and two factors: their target industries, and the materials used. At the time, 3D printers were utilized only at the R&D or prototyping stage. MSLA printing, on the other hand, is best for what he labels “high-throughput production use-cases.”

Basically, if you’re not using 3D printing that heavily, speed won’t be an issue. And if the automobile and aerospace industries are interested in printing metals to make end-use parts while you’re using polymers for your proprietary MSLA tech, it’s just not going to work out.

PIVOTING TO DENTAL PRINTERS AND MATERIALS

Entrepreneurs always remember their first customer. For Huub and Structo, Customer #1 did more than contribute to the bottom line: he got the company to change direction.

“He had bought our printer, and we learned from him what he was using it for: the production of dental models to create clear aligners,” Huub says.

This customer had his Structo-made printer running almost all day to make plastic braces for his patients. This finding meant that the company got its desired high-throughput use case, but it also presented another opportunity. Continuous printer use entails recurring resin sales—a 3D printing substance Huub likens to ink in regular, consumer-oriented printers—and that means repeat purchases.

“We started attending dental trade-shows to learn more about this market, started working on the regulatory registration of our resin materials, and slowly built a foothold in that market,” he adds.

DOUBLING DOWN ON THE DENTAL INDUSTRY

Five years on, Structo has also grown from just four co-founders to 100 employees, with more than 80 of them working out of the main Singapore office. However, the company has also set up offices where their customers are—Los Angeles, Toronto, and the United Kingdom.

The team is now focused only on the dental industry, providing four 3D printing solutions covering practices of all sizes across five continents.

Structo’s Velox printer has the smallest footprint of the bunch and is meant for individual dentists and orthodontists. Huub describes this model as ready to use and requiring minimal user input from printing, all the way to washing, rinsing, and curing.

Next is DentaForm, its flagship 3D printer that’s more suitable for dental and orthodontic laboratories. “It can produce up to 10 models in 30 minutes, and most of our customers now have at least two or three of these machines running in parallel,” Huub says.

For those with bigger but also varied printing requirements, Structo also provides custom automation solutions that are developed from scratch.

These bespoke solutions can scale along with the companies that use them like dental labs and clear aligner manufacturers.

Structo’s co-founder notes that “we already have seen great demand from both our existing and new customers because many operate in high-labor cost countries and are looking for efficient automation solutions.”

The company is also accepting pre-orders for this system, with release scheduled for mid-2020.

The other products on its roster include photopolymer printing materials from its materials division Structomer; a post-curing unit; and custom, multimillion-dollar automation systems for dental manufacturing enterprises producing thousands of models per day.

Structo currently counts the largest Swiss-made aligner brand Bestsmile, industry pioneer Inman Orthodontics, and Singapore-based clear-aligner maker Zenyum among its international clients. The deeptech startup has also gone into partnerships with Materialise and uLab Systems for MSLA-optimised software and production streamlining, respectively.

CHASING THE GAPS

As for market expansion, again, Structo has a unique situation to deal with. Unlike other startups that are only now looking at going beyond their home bases, Structo’s hyperfocus on the dental industry has enabled it to scale early. In fact, its printers are now used in most countries around the world, and the team has created a digital dentistry software ecosystem to boot.

“[It] seems trivial, but it is actually very powerful because it allows us to focus on just this one thing and excel at it,” Huub explains.

Structo’s hyperfocus on the dental industry has enabled it to scale early.

Structo’s global presence means it has a global support team providing 24/7 technical assistance to its clients and current markets. It also foresees a stronger presence in Europe for 2020, thanks to its two new UK hires.

Structo’s small company size and its coverage of both hardware and software belie its status as “the world’s largest dental 3D printing company.” It’s now in the enviable position of being able to develop and offer integrative solutions instead of answering just one concern and leaving the rest up to their customers.

It also helps that from the start, the co-founders all knew they needed to include people from outside their initial group to capitalize on the existing opportunities. “It was essentially a matter of recognizing that we were not going to be the most capable when it comes to business development and sales,” Huub explains.

This openness also applies to other parts of the business: from software to product and manufacturing engineering and materials formulation. And while the concerns have shifted to operational tasks these days, he says that “we’ve always relied on bringing in people with more experience than ourselves to help us prevent the preventable, and scale most efficiently.”

Thus, Structo was able to achieve significant sales and product development to keep chasing gaps in the dental market.

GETTING MORE SMILES

Structo has made massive progress within its relatively short corporate lifespan. More recently (in October 2019), it had secured additional funding through investors such as Wavemaker Partners, EDBI, and Temasek Holdings’ Pavilion Capital. They’ve come a long way.

“In 2014, deep tech wasn’t exactly a popular area of investment. We had our first taste by seeding dental 3D printing solutions provider Structo together with the National Research Foundation. While we were not looking actively at deep tech then, we eventually built our conviction that this was a valuable area that saw too little love compared with more popular areas like e-commerce, marketplaces, or fintech,” said Paul Santos, managing partner of Wavemaker Partners, in a Business Times exclusive.

Huub declines to state the exact amount for this latest funding round but says that Structo may have another round in the middle of 2020 to sustain its next growth phase.

As every startup can attest to, its investors provide much more than the needed financial backing. “Wavemaker Partners has been tremendously helpful to our growth, in particular in the early days when we were purely focused on product development and engineering,” he says. “Wavemaker’s team helped us on everything from finance, legal and operations, to fundraising and press/marketing.

“As we grew, we brought these functions in-house, obviously. But Wavemaker is still on our board, and we enjoy a very close working relationship with Paul and his team—always available as a sounding board, devil’s advocate, and generally providing mentorship, guidance, and resources whenever we need it.”

Structo is helping the fight against COVID19 with test swabs and face shields. Find out more about what they’re doing and ways to collaborate here.